Technology and Development

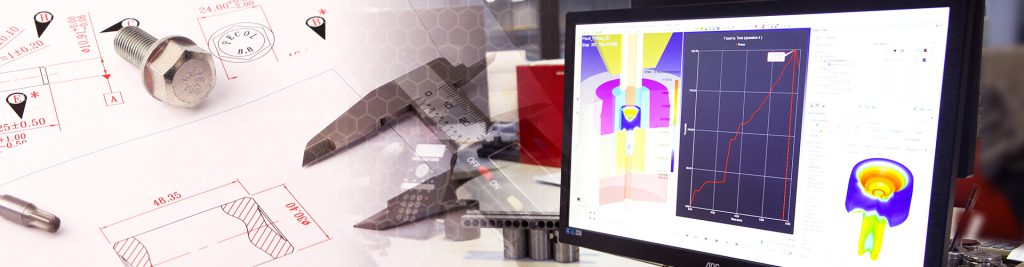

At PECOL AUTOMOTIVE, the development of 300 new products per year and the following technological evolution play a fundamental role in the company’s growth. Therefore, the Engineering department has a team of highly qualified engineers, with know-how acquired through increasingly complex projects and a focus on training people. The growth and development of the department allows a great capacity for innovation and development of new products and solutions, with which Pecol Automotive is able to satisfy all its customers.

PECOL AUTOMOTIVE has as a rule the intensive analysis of the production viability of new items, studying them in depth and deciding which are the best equipment, tools and investments to apply. With this feasibility analysis, the company is able to meet all the customer’s demands and guarantee their satisfaction.

From the conception phase of a new project, all the company’s efforts are directed towards learning, continuous improvement, sustainability, and the trust of partners, so that the industrialization of a product is successful.

Equipped with advanced technology in all processes and relying on complementary companies within the group, PECOL AUTOMOTIVE’s mission is to serve the customer with total process control, from tool design and production to the 100% selection of all items.

Tooling Design

Developing and manufacturing tooling in-house is one of our competitive advantages. With the experience and permanent training of our technicians PECOL AUTOMOTIVE has become a major center of competence in tooling development for the cold-forming industry.

PECOL AUTOMOTIVE has invested in the development of new machines/CNC equipment, managing to find innovative solutions through the development of specific algorithms for their equipment, improving this way their production processes with regard to accuracy and surface finishing. The use of CAD/CAM systems are widespread to all processes linked to the production of special tools.

Due to the increasing demand for powder metallurgy steels, hard metal with technical finishes in PVD. These materials allow a compromise between high wear resistance and impact resistance, even when exposed to extremely aggressive conditions.