– 4 logistic platforms: -Italy -Poland -Portugal -Spain Packaging and labeling according to customer requirements.

– 100% Product Verification (Part by Part) – Optical Sorting Process – Dimensional Control – Eddy Current (crack and hardness control) The average speed of sorting is 250 pieces per minute.

– 4 electrolytic lines – Friction Coefficient Control – 3 geomet lines – Corrosion Protection – Geomet® | Geoblack® | Plus® | Geokote® | Zintek® | Techseal® | Zinc Plated | Zinc Nickel | Phosphated | Nickel | Tin

– 3 Furnaces – Quenching and Tempering: 3 tons per hour – Grades 6.8, 8.8, 10.9, 12.9 stress relieving annealing

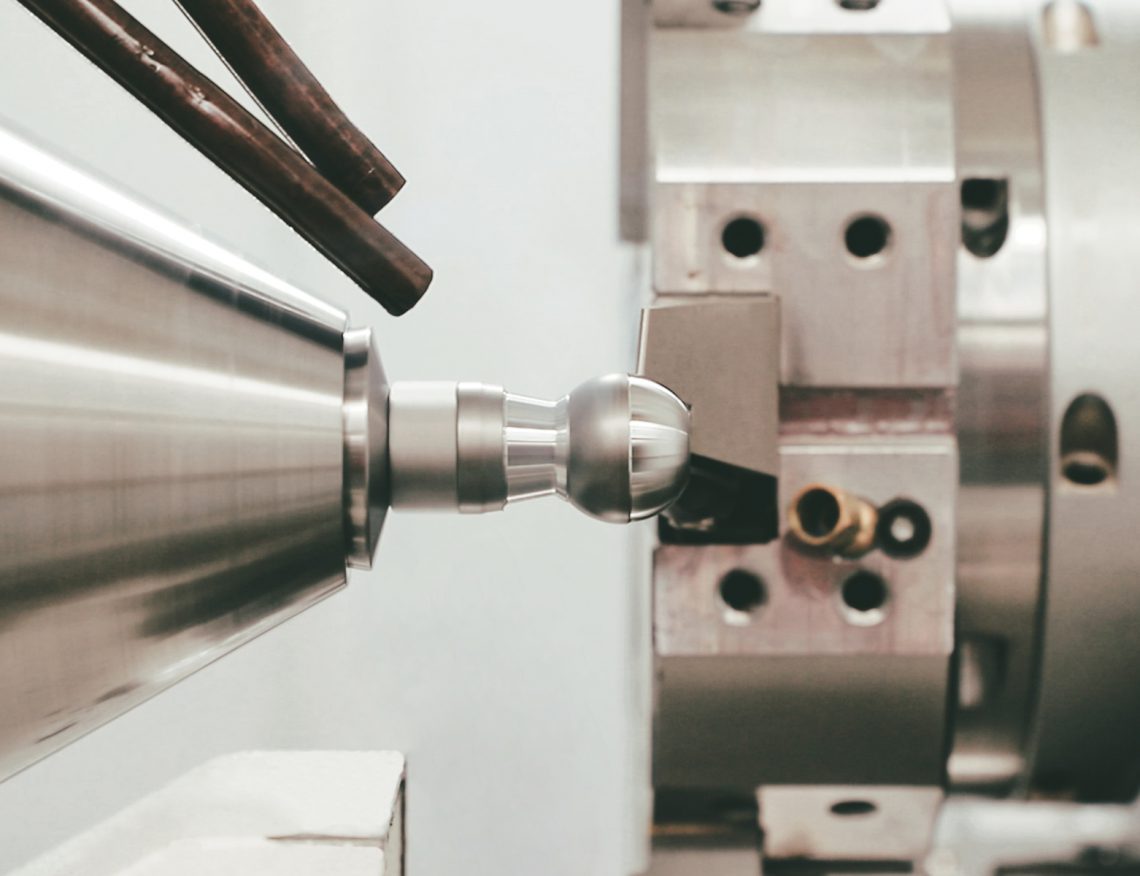

– High precision machining – Cold Forming Support Process and from steel bar Feeding – Diameter up to 40mm – Flexibility Oil recycling/reuse system installed to drain used oil from chips and scrap

– Lamination process – No material waste – Metric, Plastic, Knurl, Collar, etc. – M3 to M33 – Assembly of captive washers

– More than 85 cold forming Machines – Cold Forming Machines from 1 die – 2 Blows up to 7 stations – Open Die Process – Up to 400 Tons – Production Capacity Diameter 3 to 33mm

– Corrosion elimination – Temporary Corrosion Protection – Lubrication The existence of corrosion in raw materials (carbon steel) facilitates the removal of the outer surface (calamine) resulting from the steelmaking process.

– Capacity: 30 tons per day – 100% hydrogen-controlled atmosphere – Stress relieving – Stabilization